Dynamic

More

- Wuxi taihu international pump valve expo 2014 will be held on September 16 in wu

- Wuhan han DE valve instrument co., LTD., multinational instruments exhibition (2

- Wuhan han DE valve instrument co., LTD., special equipment manufacturing license

- Sinopec's search share $600 million cake valve supplier

- Private pump valve independent innovation to solve China's

- Technological innovation, the network marketing combination pump valve industry

- Through ISO9001 quality management system certification audit smoothly

- Cnooc is expected to be completed ChanChang's largest

- On November will have a batch of new standard valves

- China petrochemical valve localization research bulletin

Introduction

Introduction MORE

Wuhan han DE instrument co., LTD. Is a focus on the international valve manufacturers, engaged in ACG brand all kinds of butterfly valve, ball valve, regulating valve and the corresponding accessories products of the production, sales and service and other business activities. After worki... details>>

- Company news

- Industry news

-

Wuhan han DE val...

Wuhan han DE valve instrument co , LTD , multinational instruments exhibition (2013)

- Wuhan han DE valve instrum... 2014-08-18

- Wuhan han DE valve instrum... 2014-08-18

- Through ISO9001 quality man... 2014-08-18

-

By 2020 the city...

By 2020 the city of Marine engineering equipment manufa...

- By 2020 the city of Marin... 2014-08-22

- Wuxi taihu international pu... 2014-08-21

- China petrochemical valve l... 2014-08-20

Product

PRODUCT MORE-

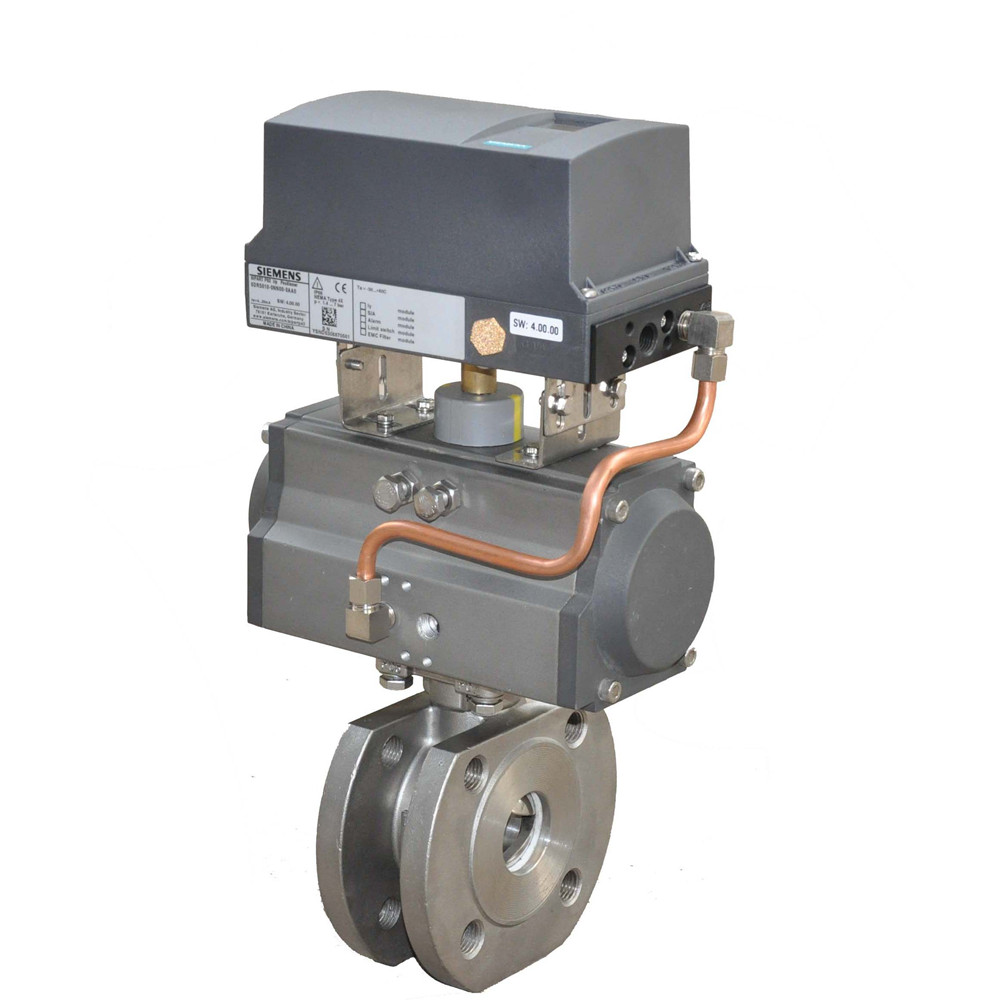

HD pneumatic...

-

HD pneumatic...

-

Pneumatic tr...

-

HD pneumatic...

-

HD electric...

-

HD pneumatic...

-

HD insulatio...

-

HD electric...

-

HD electric...

-

HD electric...

-

The HD type...

-

HD high pre...

-

HD pneumatic...

-

Instrument accessories

-

Electric cer...

-

Damper electric actuators

-

Pneumatic fi...

-

Pneumatic te...

-

Ball valve series

Community

FOURM MORE- 武汉专业阀门-ACG汉德阀门论坛... 2014-09-04

- 会员积分规则奖励,VIP奖励机制 2014-09-04

- 中国的阀门分类(2) 2014-09-04

- 中国阀门的分类(1) 2014-09-04

- 版主必看关于站内人员职责要求 2014-09-03

- 关于严禁帖、广告帖、垃圾帖、... 2014-09-02

- <会员必看> 会员注意事项简述 2014-09-02

- 阀门行业知识

- Ball valve series

- Butterfly...

- adjusting series

- Attachment

- Special-pu...

-

阀门定义

2014-09-02 -

清洗步骤

2014-09-02 -

装配及验收要求

2014-09-02 -

中国阀门的分类(1)

2014-09-02 -

中国的阀门分类(2)

2014-09-02 -

阀门行业是什么?

2014-09-02 -

阀门技术是依靠什么支...

2014-09-02 - MORE

-

HD insulation pneumatic ball valve

2014-08-15 -

HD electric cutting ball valve (HQ)

2014-08-15 -

HD electric regulating ball valve

2014-08-15 -

HD electric 3-way ball valve

2014-08-15 -

The HD type cutting ball valve

2014-08-15 -

HD high pressure ...

2014-08-15 -

HD pneumatic cutting ball valve

2014-08-15 - MORE

-

HD pneumatic high...

2014-08-20 -

HD pneumatic high...

2014-08-20 -

Pneumatic triple e...

2014-08-20 - MORE

-

HD pneumatic membr...

2014-08-15 -

HD electric single...

2014-08-15 -

HD pneumatic diaphragm valve

2014-08-15 -

Pneumatic film thr...

2014-08-07 - MORE

-

Instrument accessories

2014-08-08 -

Damper electric actuators

2014-08-07 - MORE

-

Electric ceramic ball valve

2014-08-07 - MORE